Work Page 12-25

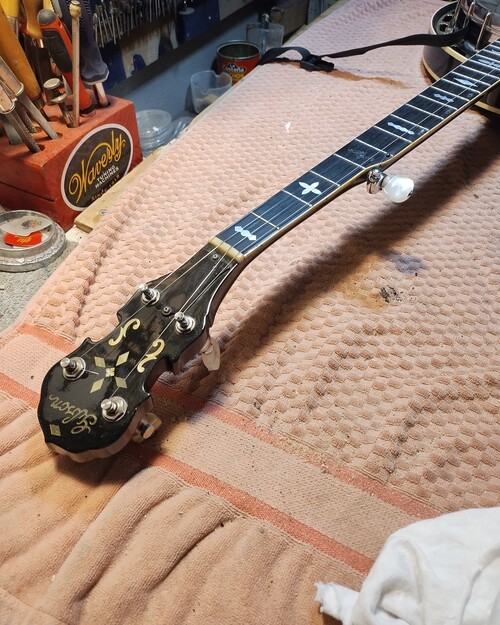

Gary's 1970s Gibson RB 250

Minor restoration and clean-up

Per customer's instructions.

Disassemble and clean/wax all metal

Clean/Wax multi-ply rim (No refinish)

Clean wax resonator (no refinish)

Secure resonator lugs in side wall

Replace worn thumscrews (4)

Re-fret 1 through 7

Refinish neck

Install missing inlay (in case pocket)

Setup on REMO clear head

Per customer's instructions.

Disassemble and clean/wax all metal

Clean/Wax multi-ply rim (No refinish)

Clean wax resonator (no refinish)

Secure resonator lugs in side wall

Replace worn thumscrews (4)

Re-fret 1 through 7

Refinish neck

Install missing inlay (in case pocket)

Setup on REMO clear head

All lugs have to be sealed in, too much thumb screw pressure over time.

New head ordered.

Cleaned/Polished, Waxed.

Neck work

Some board wear, 1-7 frets show wear.

End nipping to fret inside binding.

Pulling the wire.

All new wire in. Ends dressed

Interesting. Recessed spikes.

All slots prepped for 147 Stew Mac.

Board cleaned and oiled.

12-24 update

After refinishing the neck and setting the banjo up, I am awaiting new thumbscrews for the resonator.

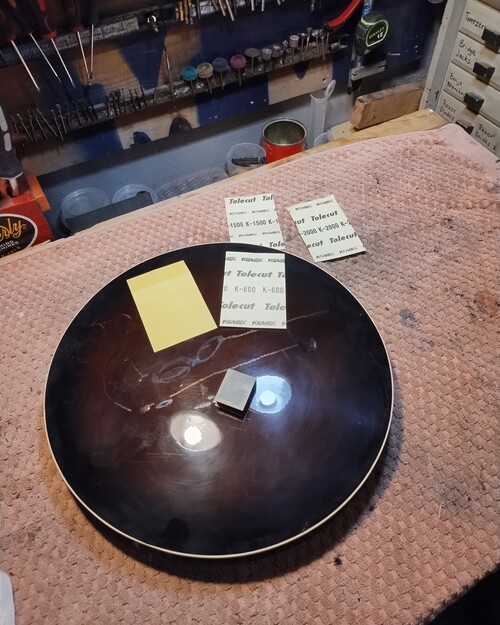

Also, the original finish on the resonator, even though in good condition for it's age, is showing some "opacity", due to photochemical reaction over time,

After wet sanding to 2000# and a trial buff, it still is dull, compared to the ne neck finish.

I will ask the customer if "buff to high shine" is still the call, or Strip/Refinish resonator so that it can show the beauty of the wood again.

When you look at "before" pics of the neck and then "after" you can see the change from opaque, to showing the wood.

After refinishing the neck and setting the banjo up, I am awaiting new thumbscrews for the resonator.

Also, the original finish on the resonator, even though in good condition for it's age, is showing some "opacity", due to photochemical reaction over time,

After wet sanding to 2000# and a trial buff, it still is dull, compared to the ne neck finish.

I will ask the customer if "buff to high shine" is still the call, or Strip/Refinish resonator so that it can show the beauty of the wood again.

When you look at "before" pics of the neck and then "after" you can see the change from opaque, to showing the wood.

Stripper to remove thick factory finish.

Tint coat applied.

New head installed.

800# paper

Final 2000# wet.

Resonator has heavy opacity, even when buffed.

Actual color of the wood.

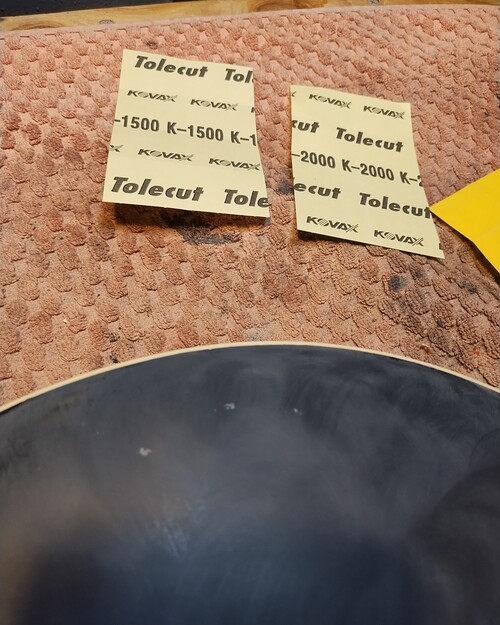

Now on to 1500#

Time to polish

Ready for tint / clearcoats.

Waiting on lacquer shipment to arrive.

Kovax Tole Cut- Block sanding.

I will drop-fill these 3 chip-outs.

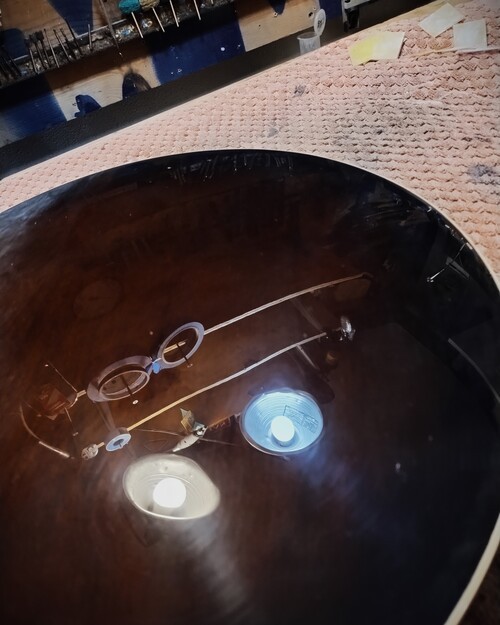

Starting to shine again.

12-26 Update

Resonator Strip/Re-finish

One reason that factories will use a darker finish, is to hide imperfections in the wood.

Not all wood is AAA presentation grade and that is saved for the higher end instruments.

Mahogany in its highest grade is very striaght grain with few deviations visible to the eye.

Gibson was no different, over time they have a dark finish many times on the less fancy stuff.

I do not consider that small a flaw being a reason to hide beautiful wood and my finish will not be as dark, just as it is not on the neck. This is a very thick finish and took 3 strippings to get to the bottom of it.

Resonator Strip/Re-finish

One reason that factories will use a darker finish, is to hide imperfections in the wood.

Not all wood is AAA presentation grade and that is saved for the higher end instruments.

Mahogany in its highest grade is very striaght grain with few deviations visible to the eye.

Gibson was no different, over time they have a dark finish many times on the less fancy stuff.

I do not consider that small a flaw being a reason to hide beautiful wood and my finish will not be as dark, just as it is not on the neck. This is a very thick finish and took 3 strippings to get to the bottom of it.

1st strip

Now to do the tint coats.

Sealer coat, ready for tint.

Tint completed, taking on clear.

Re-seating on lug anchor.

Tapping 8-32 NF threads on lugs, cleaning loc-tite from threads.

Now for the side.

Inside stripped.

Inside tint, adding clear.

Finish complete.

Chasing bad threads with 8-24 NCdie.

These are the type of flaws mentioned,

Flange lip re-dyed black.

Sidewall tint, adding clear.

Installing new felt.

Resonator completed.

Head was adjusted final time, all waxed.

FINAL PICS

Thanks for looking and sharing, VM