Workpage 12-2022

1917 Vega

Model 202 Mandolin

Ser# 385xx

Cylinder back style

Spruce top

Mahogany back and sides

Mahogany neck

Original top had caved in

Back cracked

Needed frets, tuners

Will create new braces and top

Sound hole will be bound in black/white

Will replace top kerfing

Pics will start from the time the back was repaired 2020

At that time I made a top for it that did not do as I had planned.

So this is a new effort from wood sourced from the guys in Fulton MO.

Cylinder back style

Spruce top

Mahogany back and sides

Mahogany neck

Original top had caved in

Back cracked

Needed frets, tuners

Will create new braces and top

Sound hole will be bound in black/white

Will replace top kerfing

Pics will start from the time the back was repaired 2020

At that time I made a top for it that did not do as I had planned.

So this is a new effort from wood sourced from the guys in Fulton MO.

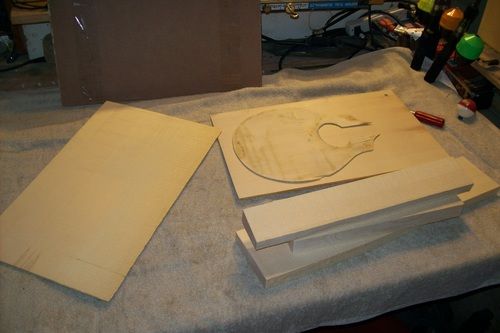

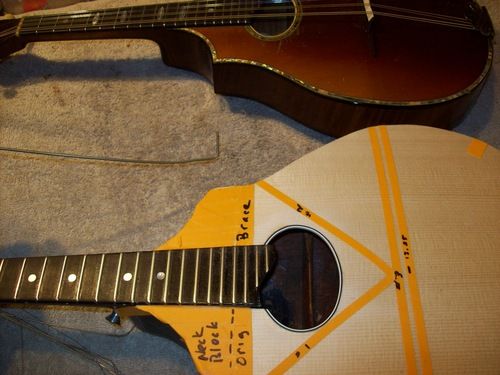

New wood and previous top

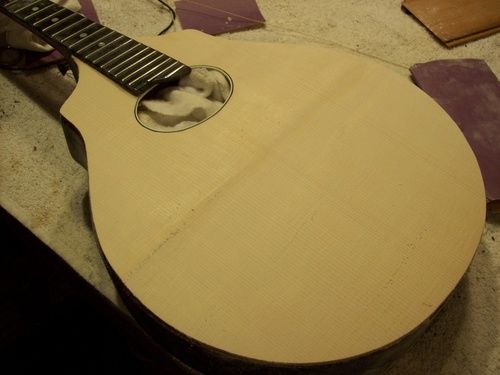

New top sanded to proper thickness

Bracewood blanks are done

Binding glued in, and flattened on both sides

Treble side installed , mahogany kerfing.

End block will get a cap of spuce

Bass side ,end block done, binding channels next

Fender Artist neck getting free exposure.

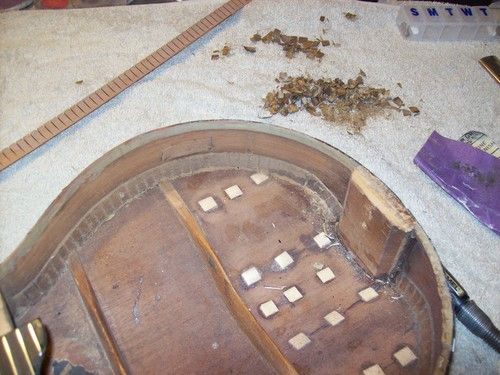

Orig top "Repairs", there was never a brace

Only repair cloth

Showing brace tips that will for sure connect to the ribs

Scales are identical, top is still not profiled

Making it look a little off but it is really close.

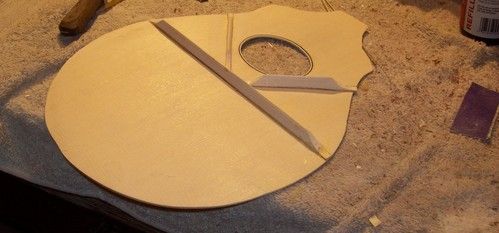

Steam bending the top after making a razor cut

This will facilitate the bending process

Ready to come out of clamps after cure

The breakover can be seen after a coat of sealer

Excellent width for the 1 piece top design

Grain is nice and striaght for braces

Ready to remove top kerfing and replace

Tye orig is poplar, as are the neck blocks

Shaping/fitting /installing new bracing

Also, when I look into my 207, there is none

I think problem was in my first bracing where the tips meet the body.

Pointing out the breakover point in the orig. top

Will place a torrified spruce brace where muslin cloth was located

Putting pressure onto the breakover area

Brand new bottle of fish glue for the install

Original brace with serial number stays in situ.

Cutting the brace wood for grain orientation

Excellent linear grain on the top

Ready to bind

I will take that down all the way to mahogany

The green color is typical for Poplar

Bass side is prepped and ready

Thin coat of sealer added to protect all the new work

Crossbraces wedged in main brace relief for rigidity

Slowly doing the cutout profile and tapering

This is the pattern ,orig one by sound hole

Open line between brace/bridge placement is for the "Break

It had many repair attempts in it's life.

The thin bracing should help impede the spruce cracking

Drying while under pressure from wedging

It will cure here 12 hrs

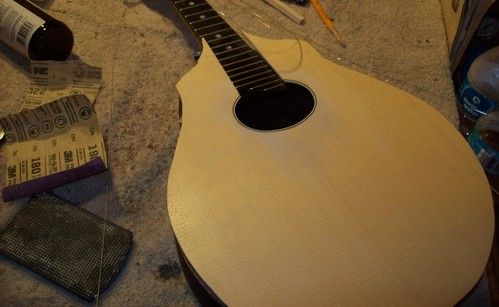

Out of clamps and profiled, repairing fboard chip

Had a piece of binding break off, will repair and go forth.

Taking on clear and block sanding.

Next will be binding channels

Next sequence

anding to the peak, both directions.

Ready to bind with white/black/ivoroid, celluloid.

Moving along, heating and bending and gluing

Sealed with clear nitro.

Working on the new binding channel

Top and side tint added

Now to sand with 400 grit

Heat gun in one hand, pushing to the curvatures with the other.

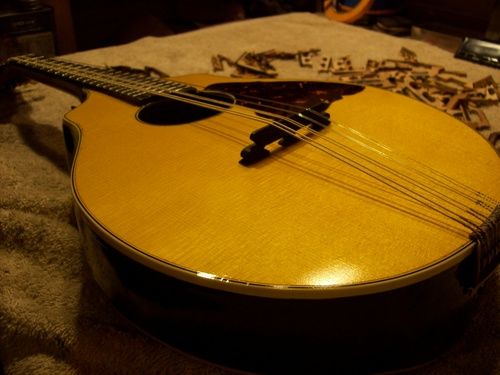

Everything taking on clear coats.

SETUP

Installing new pickguard

Action and string angle good.

Picking a bridge

Searching for a "cloud" tailpiece cover.

Changing back to correct period tuning machines

Will go with this one for the setup

Thanks for looking and sharing.

VM

VM